-40%

Hangsterfer's S-500 CF 5 Gallon pail

$ 63

- Description

- Size Guide

Description

You are getting a brand new and sealed 5 gallon pail of Hangsterfers S500CF coolant.S-500CF ®

A Boeing approved product for general machining of all metals. Due to its extreme pressure (EP) properties, outstanding results have been generated on all metals, including nickel alloys, stainless steels and aluminum alloys. Our CF version is chlorine free with specially formulated anti-weld and anti-wear compounds for use on ferrous and non-ferrous metals especially aluminum alloys.

S-500® CF Coolant Concentrate: Water Soluble Oil

FEATURES Chlorine Free Extreme Pressure Technology Maximizes Tool Life Excellent Sump Life Non-Hazardous General Purpose Non-Irritating Long Lasting And Bio-Stable Non-Toxic

Approved, Certified, and Conforms to: Airbus, American Airlines, Boeing, Bombardier, LockheedMartin, Lord Corp., Messier-Buggati-Dowty, Pratt & Whitney, United Technologies, and Rolls Royce

GENERAL DESCRIPTION The first choice for general machining for all metals and non-traditional materials. The EP properties produce excellent results over a broad range of manufacturing conditions. This general purpose product satisfies some of the most demanding manufacturing operations from stamping, milling and turning processes. Amine free and safe on all materials while providing the best finishes and tool life on aluminum, steel to stainless steel.

APPLICATIONS Primary Secondary Blanchard Reaming Burnishing Forming Drilling Stamping Broaching Surface Grinding Milling Turning Creep Feed Grinding

MATERIALS Primary Secondary Aluminum Plastics Brass Glass Chromium Alloys Powdered Metals Bronze Graphite High Temp Alloys Precious Metals Ceramics Refractory Metals Molybdenum Steel Copper Stainless Steel Nickel Alloys Titanium

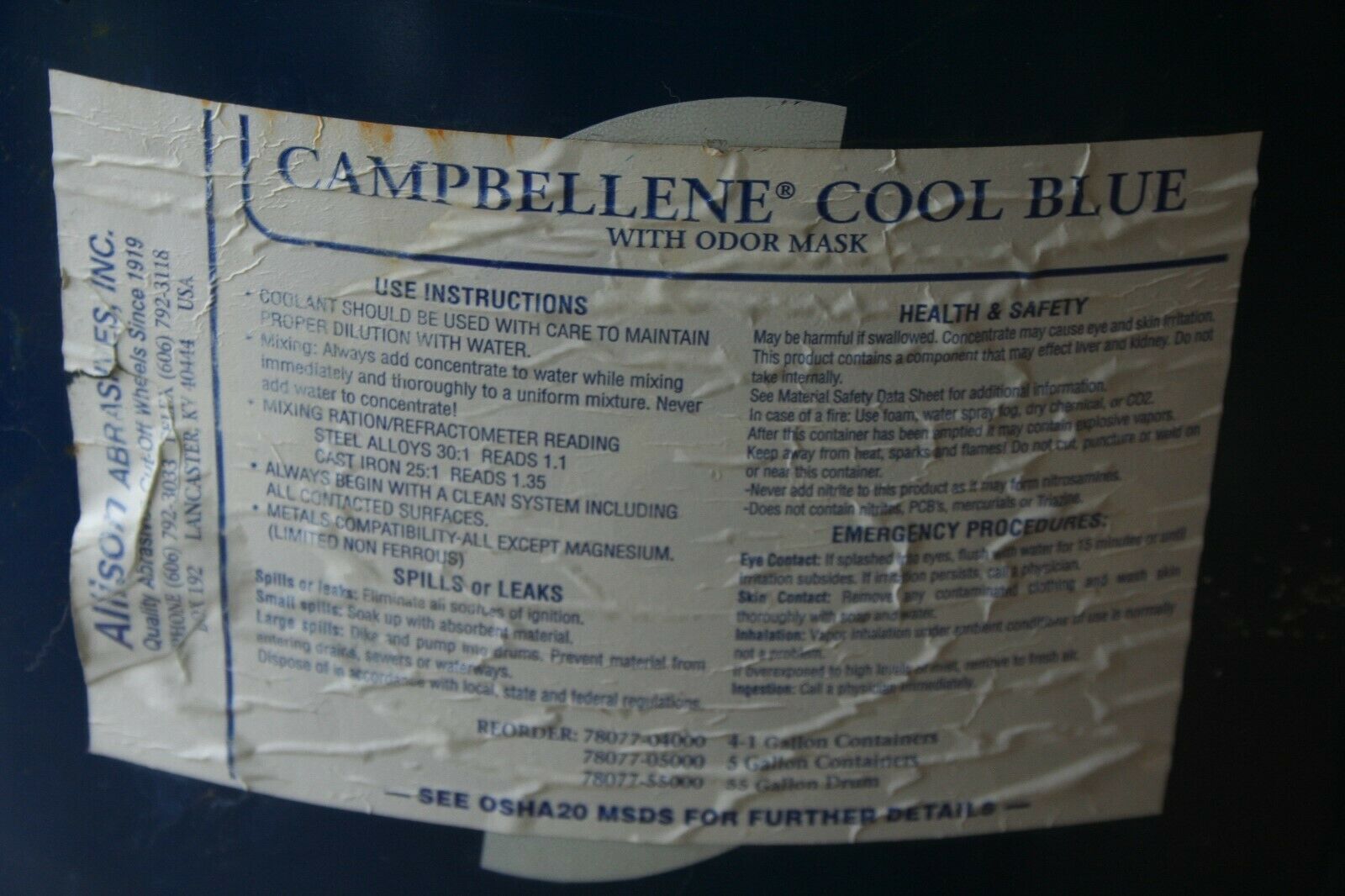

INSTRUCTIONS Always premix coolant before adding to the machine sump. When mixing coolant by hand it is important to always add the concentrate to the water and then agitate. For best results, a Hangsterfer’s recommended proportioning unit should be used. To maintain recommended concentration, make-up should be added at one-half the desired concentration. Always check concentration with a Refractometer. To maintain 6%: first charge the machine at 6%, then, as needed, add make-up as much as 3%. Avoid adding straight water or concentrate directly to the machine. OPERATION CONCENTRATION % Ratio Concentrate: Water Refractometer General Grinding 5 1:20 5 General Machining and Turning 7.5 1:13 7.5 Grinding with aggressive feed rates 10 1:10 10 Drilling, Tapping, Reaming 10 1:10 10 Light Stamping and Forming 10 1:10 10

MAINTENANCE S-500 CF is a bio-stable coolant, designed to control the growth of bacteria. Regular maintenance is required for maximum performance. Concentration should be monitored regular with a calibrated refractometer. S-500 CF gives a direct read on the refractometer (E.G. 5=5%).

WASTE TREATMENT Dispose of in accordance with local, state, federal and international laws. If and when it is necessary to dispose of waste fluids, the amount of waste can be greatly reduced by separating the water from the oil and contaminants which accumulate through normal machining. You can often reduce your waste disposal by more than 80% through conventional methods such as Ultra-Filtration, Chemical Treatment or Evaporation. After approval by your local, state, or federal authorities, the waste water may sent to the sewer or discharged into waters, and the separated oils may be removed for recycling, sale or disposal.