-40%

Blum Labelling Machine Legi Air 4050E Etikettendruckspender Weber " Top State "

$ 8264.1

- Description

- Size Guide

Description

FLOWER /weaver

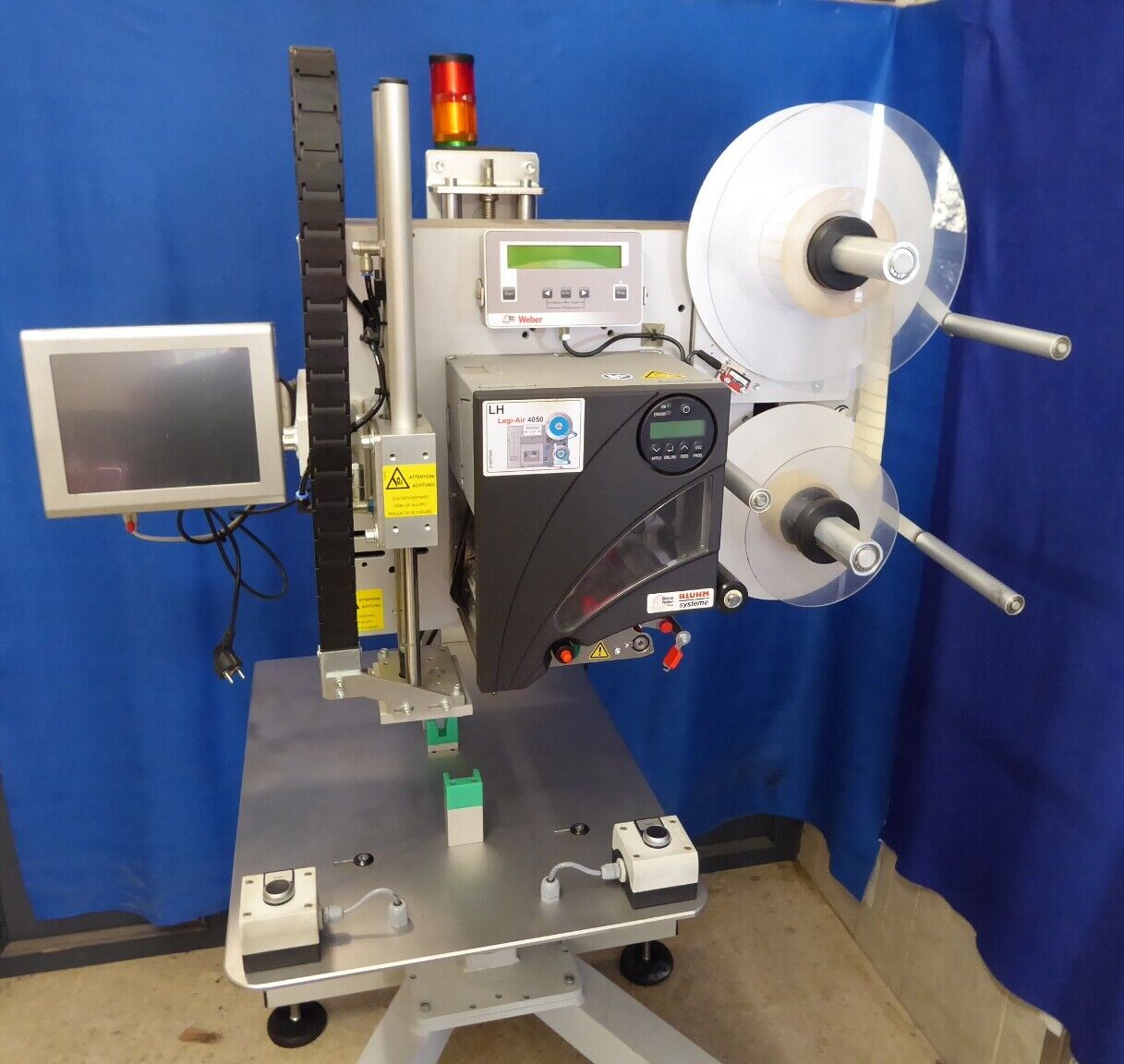

Labeling machine LEGI AIR 4050E

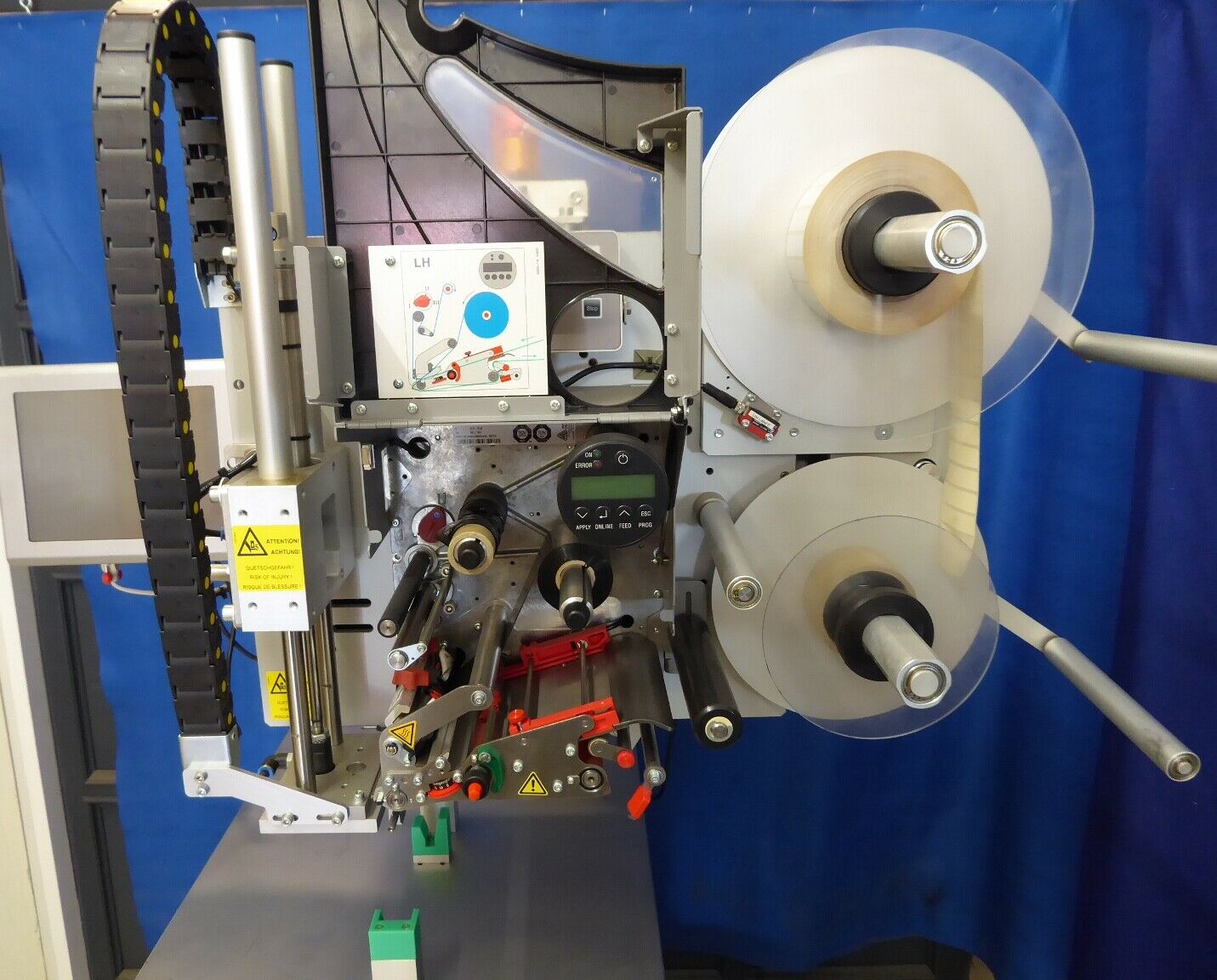

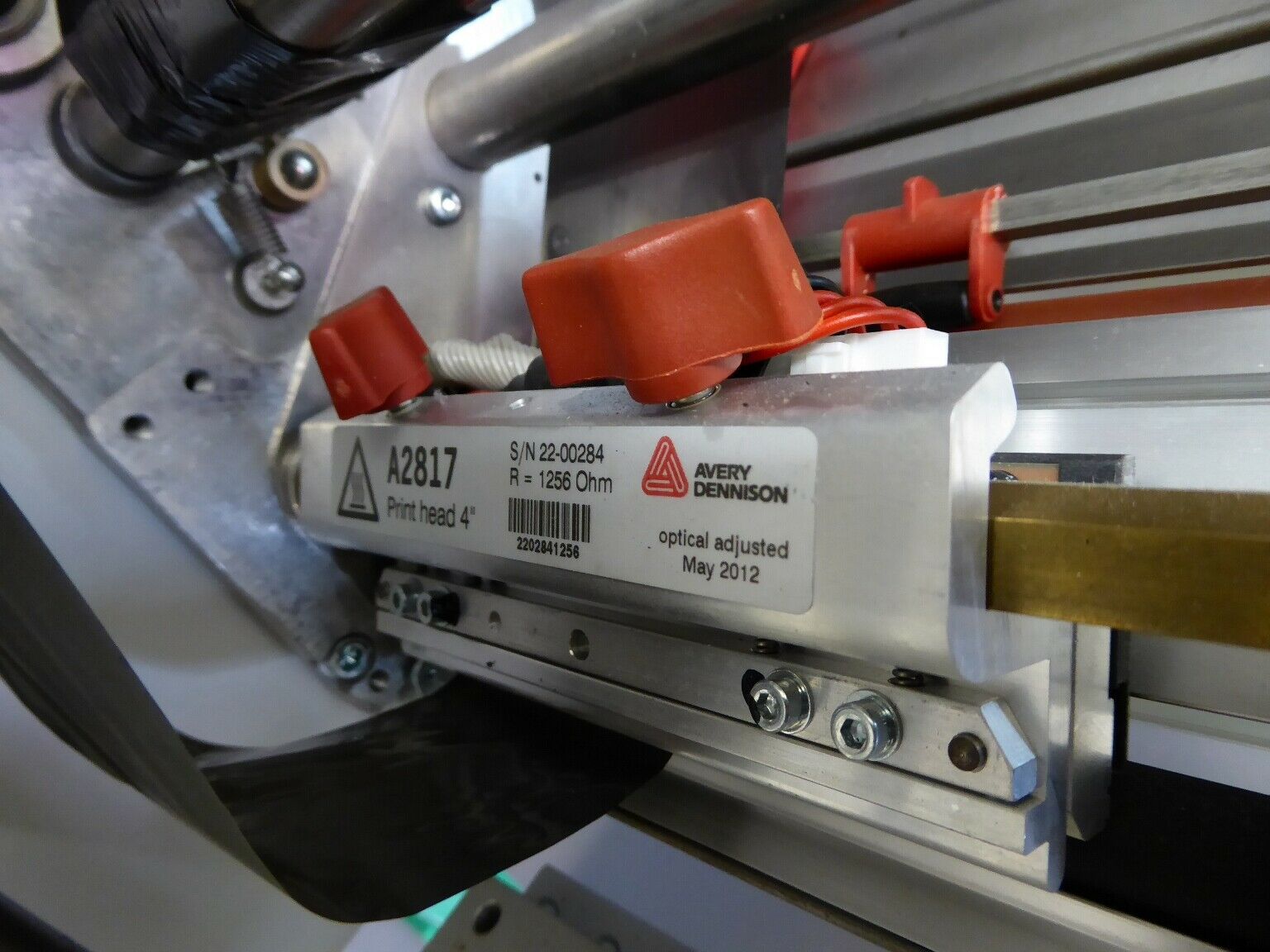

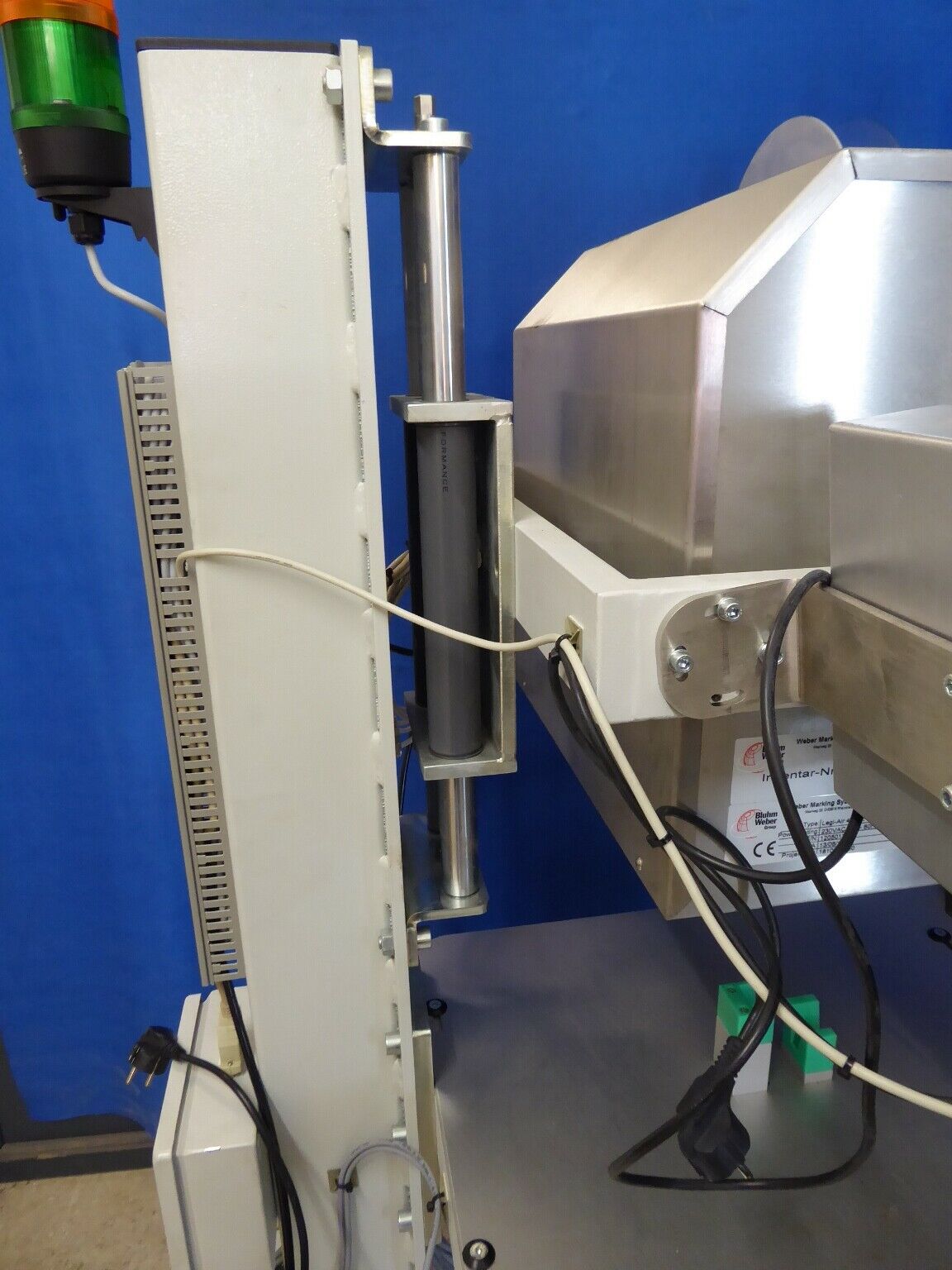

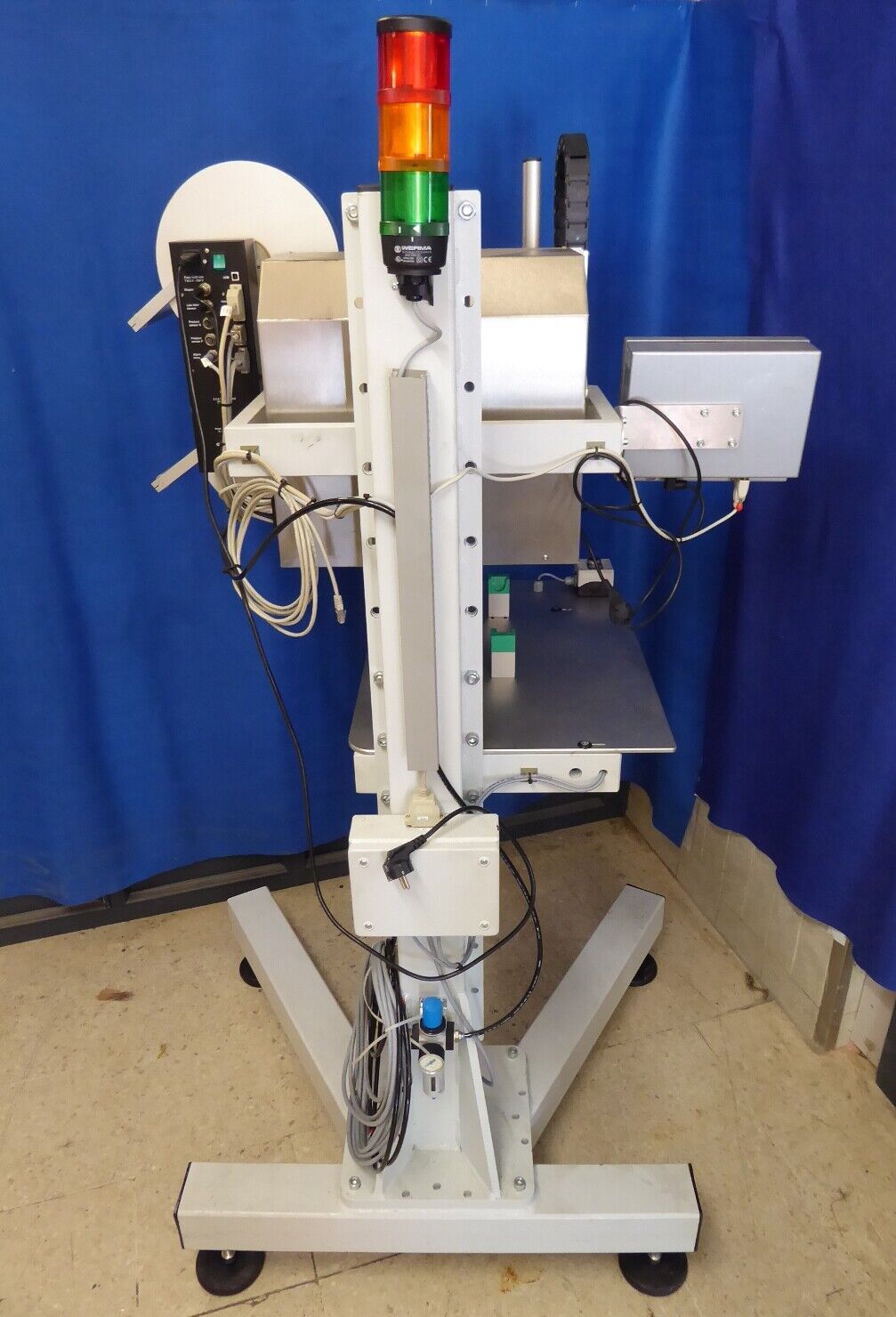

Dispenser module, print module, label winder and unwinder, applicator and industrial PC

(New price was 29,000 euros)

Overview Legi-Air 4050 E

Flexible and powerful

Labeling is done from above. The mode of operation also enables high-speed labeling applications and a direction-independent positioning of the labeling system on the product. Of course, a number of other application variants are possible, eg stamping and wiping labels. If required, the dispensing systems are controlled and networked using the Legitronic® labeling software. This increases throughput times and increases production reliability.

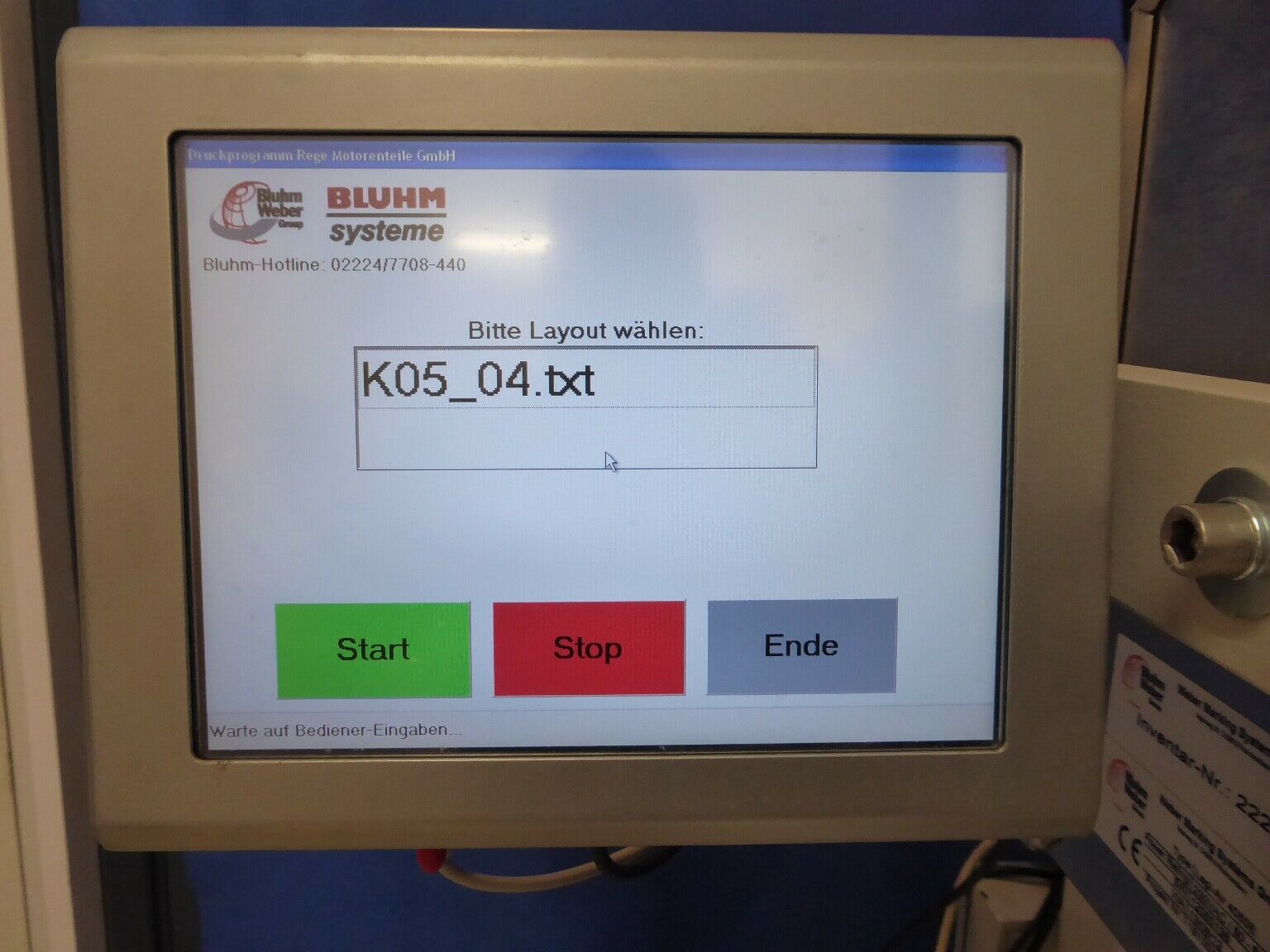

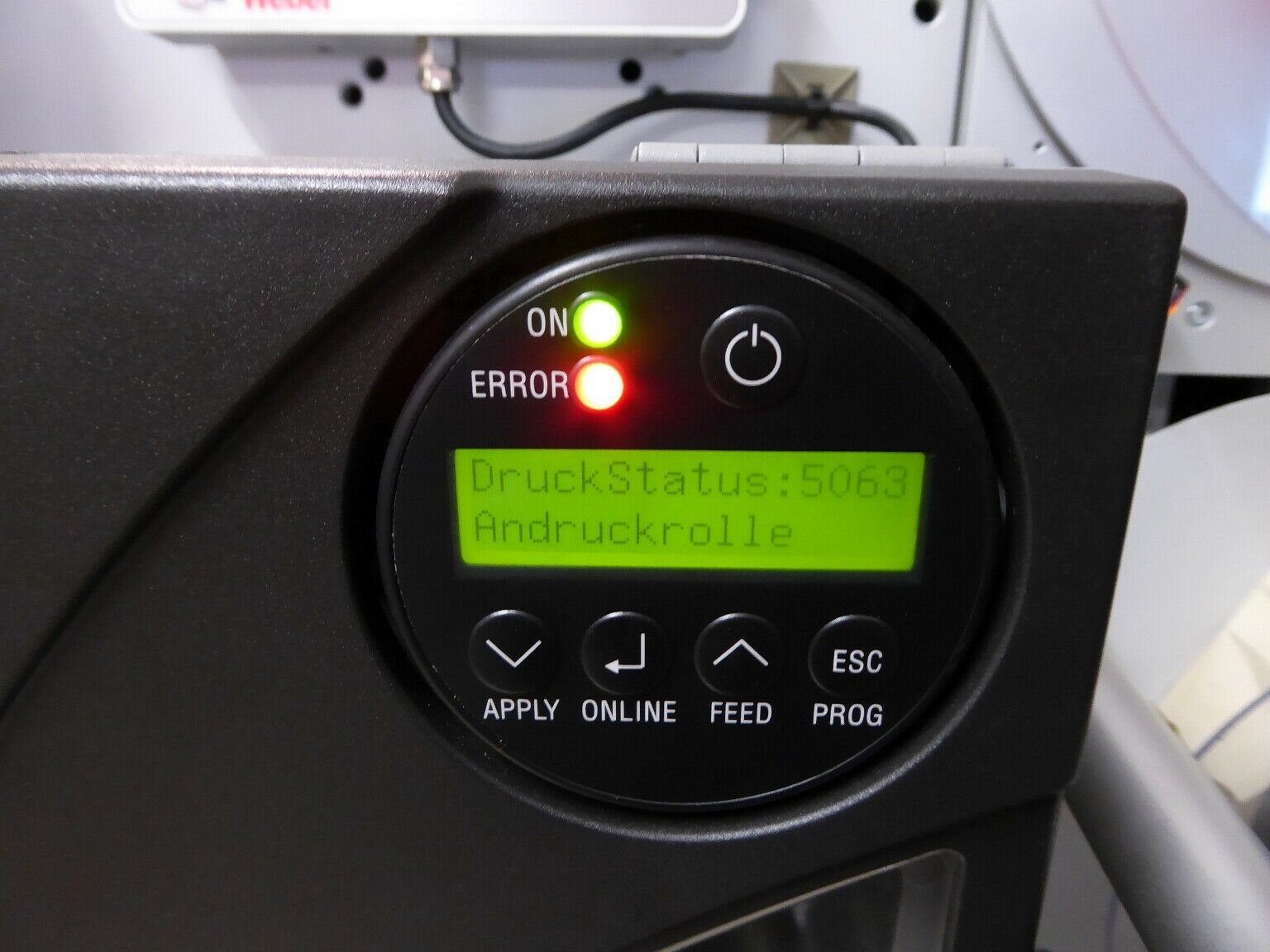

Trouble-free operation

A display controller with a large multilingual text display enables easy operation. Targeted operator information on the machine status is displayed in plain text. Storage options for label and product-specific parameters, which can be called up quickly and repeatedly. The display controller is removable if required. In the case of complicated installation positions of the pressure dispensers in production, entries can also be made in a user-friendly manner. A motor-driven rewinder ensures that the label web runs quickly and in a straight line, thus guaranteeing that the labels are printed with precision.

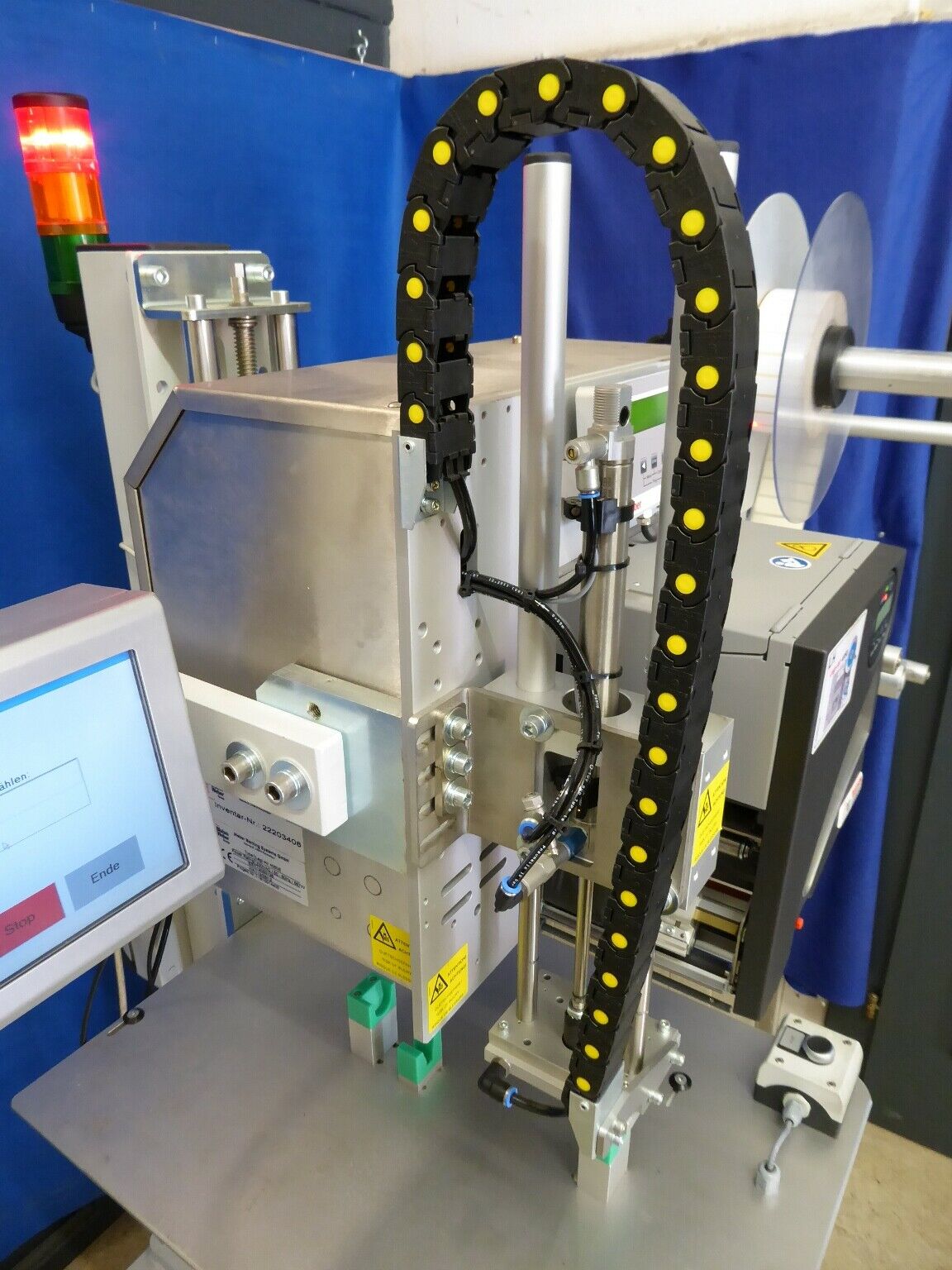

Process reliability through flexible adaptation to the label material

A two-stage vacuum for label transport and dispensing enables flexible adaptation to the label material (hard or soft) and guarantees process reliability when labeling. Exactly the vacuum is built up that is needed for safe label transport on the dispensing stamp on the one hand and that is required for application on the other hand. Control electronics and pneumatics are protected from adverse environmental influences by a stainless steel housing. A material shortage sensor prevents unplanned system downtimes.

cost saving

The system parameters can be transmitted via USB. System and maintenance information ensures quick and easy diagnosis.

The system is optimized for the following parameters:

Installation position 1, ie labeling from above onto the product

Product order: messy

Products are labeled in the stopped state.

Product heights: from 5 to 595mm

For conveyor belt width 450mm to 650mm; the products must always be aligned to the side on which the print dispenser is located. An optional inclined roller conveyor is suitable for this.

Ethernet interface to the FlexConveyor controller

Incl. tripod

Schedule

Thanks to its compact modular system base, the Legi-Air 4050 E can be expanded at any time for a wide variety of applications, eg with special donation stamps or barcode control devices. E is synonymous with the word ENHANCED. Behind this lies the system diversity based on the modular design. This consists of a dispenser module, print module, label winder and unwinder and the LWA600 applicator.

Print time: 0.8sec (with optimal print time without backfeed)

Extend cylinder, blow off label: 0.7 sec

Cylinder retraction: 0.5sec

This results in a total cycle time of 2 seconds, whereby you can parallelize certain cycles by releasing the product after blowing off.

phone 0 1 7 2 - 9 3 6 0 8 02

technical data see pictures or

Requests

International buyers welcome

please ask for shipping costs to Europe and overseas

A display controller with a large multilingual text display enables easy operation. Targeted operator information on the machine status is displayed in plain text. Storage options for label and product-specific parameters, which can be called up quickly and repeatedly. The display controller is removable if required. In the case of complicated installation positions of the pressure dispensers in production, entries can also be made in a user-friendly manner. A motor-driven rewinder ensures that the label web runs quickly and in a straight line, thus guaranteeing that the labels are printed with precision. A two-stage vacuum for label transport and dispensing enables flexible adaptation to the label material (hard or soft) and guarantees process reliability when labeling. Exactly the vacuum